-

Anfeng Industrial Park, Dongtai City, Jiangsu, China

-

WhatsAPP: +86 19941574798

Our TQM system ensures rigorous quality oversight across the entire product lifecycle, from raw material inspection to final delivery, guaranteeing zero-defect performance.

Driving innovation through advanced R&D and precision engineering to transform complex concepts into market-ready products with optimized manufacturability.

A globally-trusted manufacturer defined by total adherence to international laws and a zero-tolerance policy for non-compliance.

As a leading specialist in polyurethane engineering, Philson provides high-performance offshore and industrial solutions. Our rigorous quality control and advanced material science ensure reliability in the most demanding environments.

The Subsea Cable Bend Protection Tube is primarily designed to protect subsea cables at the lower outlets of I-tubes and J-tubes in offshore wind power applications.

Bend stiffeners are conical polyurethane moldings used to control the minimum bend radius of flexible pipes and sustain cyclic fatigue loads at rigid connections.

High-performance dynamic cables engineered with lazy-wave buoyancy and fatigue-resistant conductors to serve as the resilient lifeline for floating offshore wind platforms.

Distributed Buoyancy Modules (DBMs) are engineered assemblies attached to flexible risers, umbilicals, and subsea cables to control the vertical and horizontal profile of a line, reduce tension, and prevent damage to the system.

Compare Bend Stiffeners vs. Bend Restrictors for offshore wind cable protection. Learn how to manage MBR, suppress Vortex-Induced Vibration (VIV). Get technical insights on dynamic vs. static cable protection.

The main function of the distributed buoyancy module for offshore pipelines is to provide buoyancy support for pipelines, enhance their stability, and thus extend their service life.

ARE YOU LOOKING FOR PROFESSIONAL POLYURETHANE PRODUCTS?

With a global network of partners, we specialize in providing high-performance products, including Bend Restrictors and Centralizers. Our expertise is deeply rooted in core sectors such as Offshore Wind Energy, Offshore Oil & Gas, Marine Engineering, and Subsea Cable Protection.

If you have more needs about technology, products and services, please contact us!

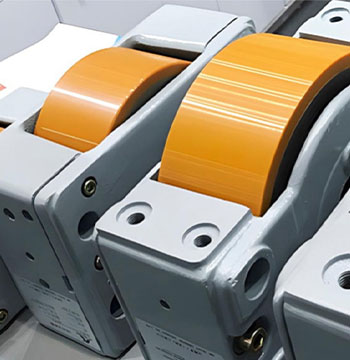

We provides customers with industry news on professional marine engineering series protection systems and polyurethane wheels.

Polyurethane J-tube seals are the core components that ensure the safety of offshore wind power cables and prevent seawater infiltration from seawater corrosion, wave impact, salt spray erosion, etc.

A Vertebrae bend restrictor assembly is a device that is mounted around a cable and attached to a structure to prevent the cable from bending beyond the designed locking radius of the bend restrictor. This helps to prevent the cable from overbending.

Cast iron and polyurethane bend restrictor each have their own set of advantages and disadvantages, particularly in terms of their application as bend restrictors for cables, hoses, or pipes.

Polyurethane bend restrictors are specifically designed for various marine and offshore applications where protection against excessive bending of cables and umbilicals is required.

Primary function of polyurethane vertebrae bend restrictor, is to protect cables, wires, and other flexible conduits from excessive bending, which can lead to damage, signal degradation, or even complete failure of the system

Bend restrictors are crucial for safeguarding submarine cables by controlling their bending radius. This prevents excessive stress and potential damage, ensuring cable longevity and reliability in challenging underwater conditions.