RGV Wheel Block Repair Measures

RGV wheel block repair is a key maintenance measure to ensure efficient operation of equipment and extend its service life. For common fault situations, the following are some specific maintenance methods:

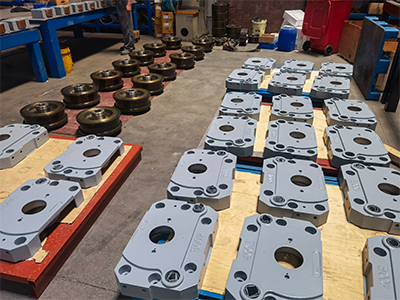

Check and Replace Worn RGV Wheels

• Steps: First, put the machine power off for a full inspection of the wheels and use tools to remove the wheel block and check the wheel for wear, including surface wear, cracks or deformation.

• Replacement: For severely worn or damaged wheels, choose a new wheel with polyurethane or other wear-resistant materials that meet the original specifications. When installing, pay attention to the coaxiality of the wheel and the shaft to ensure balance.

Adjust the RGV Wheel Base and Alignment

• Check: Use measuring tools to check the distance between the wheels, including the span and diagonal, to ensure that the deviation is within the allowable range.

• Adjustment: If the deviation is found to be too large, it can be fine-tuned by adjusting the spacer ring or fastener of the bearing seat, and repositioning the wheel if necessary to ensure wheel alignment and reduce vibration and offset during operation.

Wheel Block Track Cleaning and Adjustment

• Cleaning: Clean up foreign matter and dust on the track, use appropriate tools to repair deformed or worn parts of the track, and ensure that the track is smooth and unblocked.•

• Track calibration: Recalibrate the wheel track with laser alignment equipment to ensure its straightness and levelness to reduce unnecessary wear on the wheels.

RGV Lubrication Maintenance

• Choose the right lubricant: Choose the right lubricant or grease based on the material of the wheel block and avoid the use of chemicals that will erode the material of the wheel.

• Regular lubrication: Develop a lubrication plan to regularly lubricate the bearings and track contacts of the wheel to reduce friction and wear and extend service life.

Detection and Prevention

• Install sensors: Consider installing wear or foreign object detection sensors at key locations to monitor wheel and track status in real time.

• Regular inspection: Establish regular maintenance inspection system, including wheel wear inspection, track condition, wheel base adjustment, etc. Preventive maintenance is an effective means to avoid failure.

The above method can effectively solve the common problems of the straight rail shuttle wheel, ensure the stable operation of the equipment, improve the operation efficiency, and reduce the maintenance cost. If you have a need to buy or replace the wheel block, you can contact Philson.We are looking forward to hearing from you.