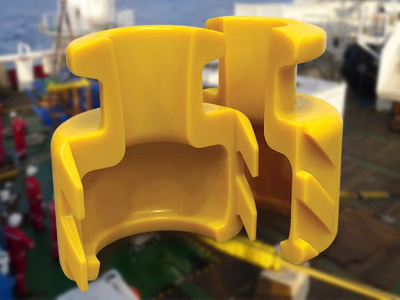

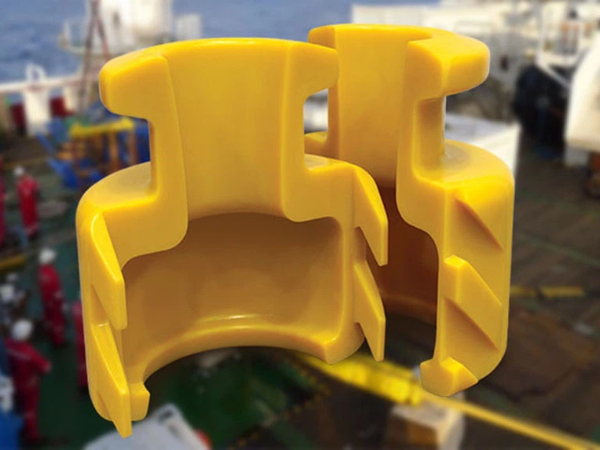

The Boltless Bend Restrictor is a pipeline protection device specifically designed for the offshore engineering sector. Its core advantages lie in installation efficiency, structural performance and cost control. It effectively addresses the issue of excessive pipeline bending during offshore operations while being suitable for long-term harsh working conditions

Core Advantages

Efficient Installation & Significant Cost Reduction: It takes less time for installation, which can greatly shorten offshore operation duration and directly translate into substantial offshore cost savings.

Innovative Structure & Optimized Strength: It adopts a groundbreaking boltless interlocking design, which can fully leverage the mechanical properties of the material itself. It ensures structural stability without relying on bolted connections.

Excellent Load-Bearing Capacity & Wide Adaptability: It has outstanding load-bearing capacity. Whether in short-term high-load or long-term continuous stress scenarios, it can stably control the degree of pipeline bending and prevent damage.

Strong Temperature Resistance & Superior Creep Resistance: It possesses excellent temperature resistance, which is crucial for the device's creep resistance performance during long-term use and enables it to adapt to the offshore environment with temperature fluctuations.

Controllable Costs & Reduced Risks: It offers prominent cost-effectiveness when multiple units are used in batches, which can significantly save the overall investment. Meanwhile, it reduces reliance on sub-suppliers and lowers supply chain risks.

Compliant Design & High Safety Reliability: The material selection and overall design methodology are fully compliant with API 17L 1 and API 17L 2 standards, meeting the strict safety and performance requirements in the offshore engineering field.