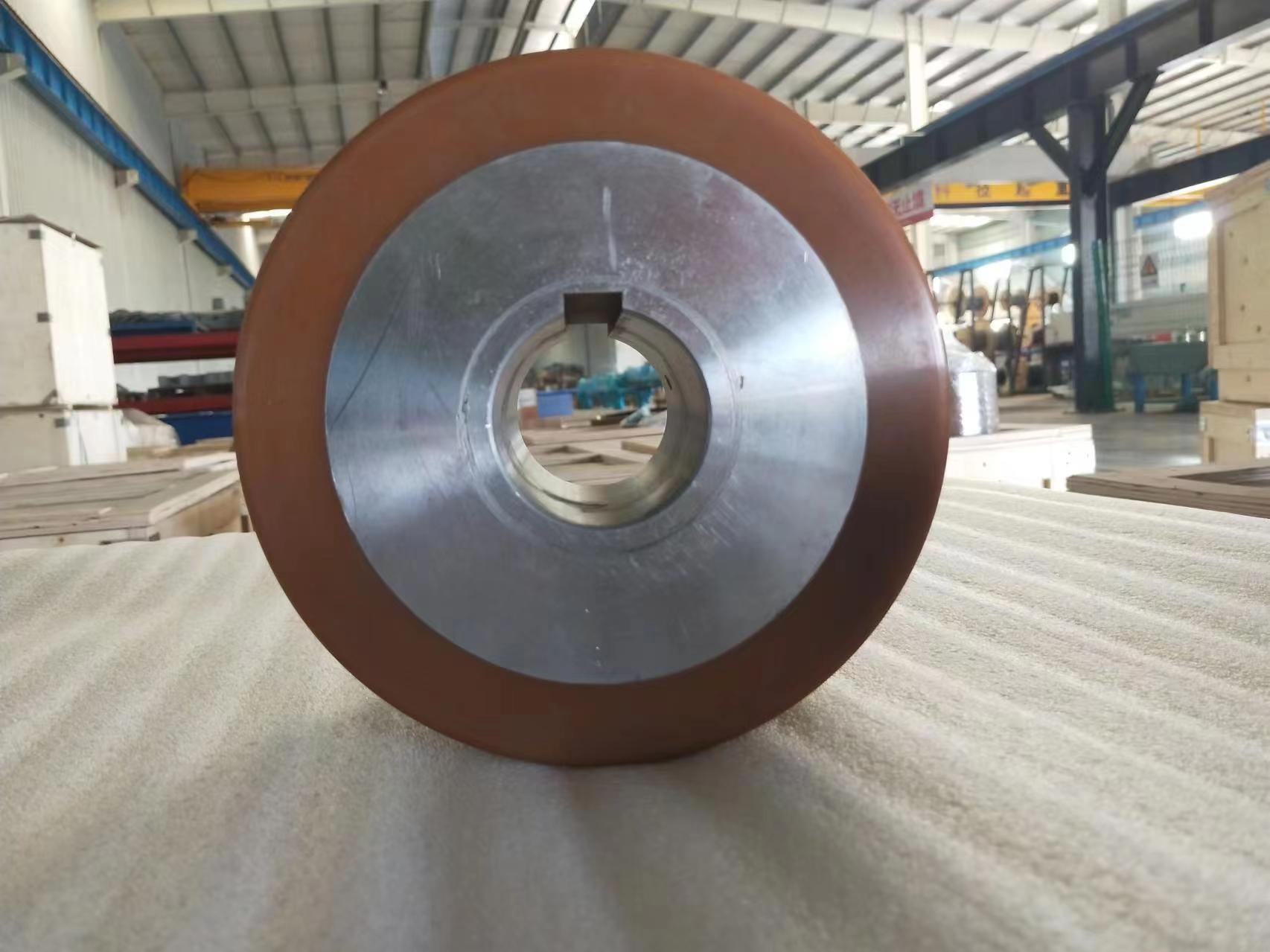

The stacker polyurethane load wheel is a high-performance wheel designed for stackers. It is coated with polyurethane material and has excellent load-bearing capacity and wear resistance. It is suitable for high-frequency, heavy-load storage environments. The elasticity and impact resistance of polyurethane materials effectively reduce the noise and vibration of the wheel during operation, while protecting the ground from damage, so that the stacker can run smoothly and accurately in the automated storage system.

Production process of polyurethane load wheels

● Material preparation: First, select a suitable substrate (such as steel or aluminum alloy) as the core of the wheel, and the polyurethane material is selected with appropriate hardness and characteristics as needed.

● Molding: The substrate is formed into the required wheel shape and hole position through milling, drilling and other processing methods, while ensuring accurate dimensions.

● Polyurethane coating: Polyurethane coating is applied to the surface of the substrate. Usually, injection molding or casting molding technology is used to evenly apply the polyurethane liquid material to the surface of the substrate, and heat and cure it to form a wear-resistant and corrosion-resistant outer layer.

● Curing and finishing: After the curing process, the polyurethane coating will be fully hardened to ensure the durability of the wheel. At this time, the wheels are trimmed to remove surface unevenness or excess material to ensure the accuracy of the final product.

● Inspection and quality control: After completing the above processes, strict inspections are carried out, including size, hardness, wear resistance, load-bearing capacity, etc., to ensure that each wheel meets the standards.

Characteristics of stacker polyurethane load wheels

● It can withstand large loads and is suitable for high-load, frequent take-off and landing stacker operations to ensure stable operation.

● The elasticity of polyurethane enables the wheels to absorb and buffer impact forces, reducing damage to equipment and the ground, and keeping the equipment running smoothly.

● Compared with traditional steel wheels, polyurethane wheels generate less noise during operation, which helps to improve the working environment.

● It has certain corrosion resistance and can be used in wet or chemically corrosive environments.

● It can maintain good performance in different temperature environments and adapt to various working conditions.

As a professional manufacturer of polyurethane wheels, Philson relies on advanced production technology and strict quality control to ensure that each polyurethane wheel can maintain excellent performance under extreme working conditions to meet customer needs in industries such as automated warehousing, logistics and transportation. Contact us now for free to get the best design plan and preferential quotes!