The mining industry operates in some of the most demanding environments, where equipment is subjected to harsh conditions and heavy loads. Monorail cranes are a vital component in these settings, facilitating the movement of materials and machinery. The wheels on these cranes play a critical role in their performance, and polyurethane wheels have emerged as a superior choice for mine monorail cranes.

Superior Material Properties

Polyurethane is a versatile polymer known for its resilience and durability. When used for wheels on mine monorail cranes, it offers several key advantages:

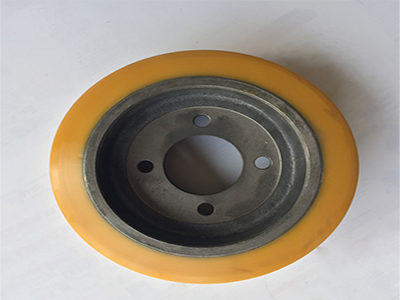

High Abrasion Resistance: Polyurethane wheels can withstand the abrasive surfaces commonly found in mines, reducing wear and extending the life of the wheels.

Load Bearing Capacity: These wheels are designed to handle the substantial weights that cranes must lift and transport, ensuring reliable operation even under heavy loads.

Low Friction: The material's natural lubricity reduces friction against the monorail, which can lead to decreased energy consumption and less heat buildup.

Shock Absorption: Polyurethane's elastic properties allow it to absorb shocks and vibrations, protecting both the crane and the transported materials from damage.

Chemical Resistance: The wheels are resistant to various chemicals, including oils, solvents, and water, which is essential in the chemically diverse environment of a mine.

Low Maintenance: The durability of polyurethane means that wheels require less frequent replacement and maintenance, reducing long-term operational costs.

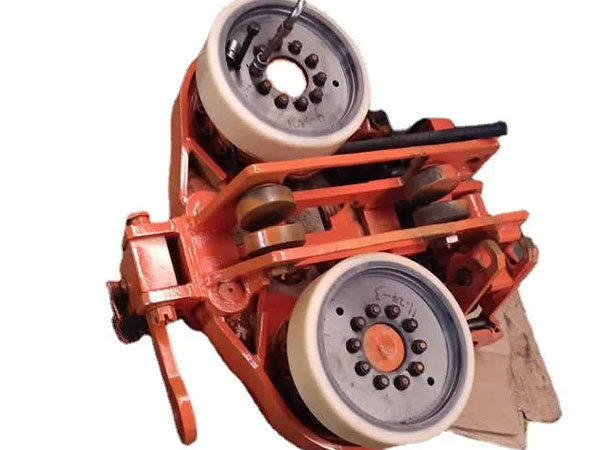

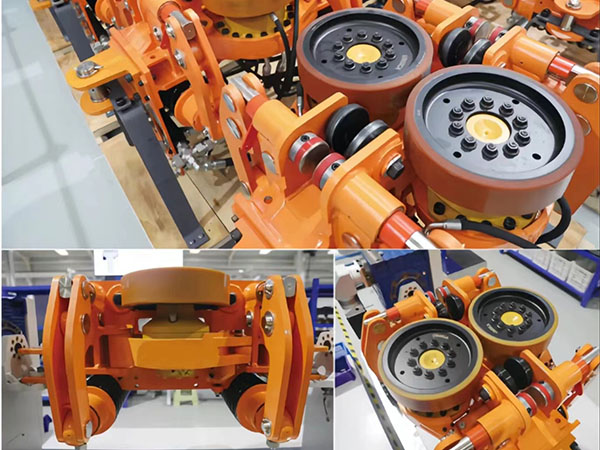

Common Models and Specifications

The variety of polyurethane wheels available for mine monorail cranes is designed to meet different operational needs:

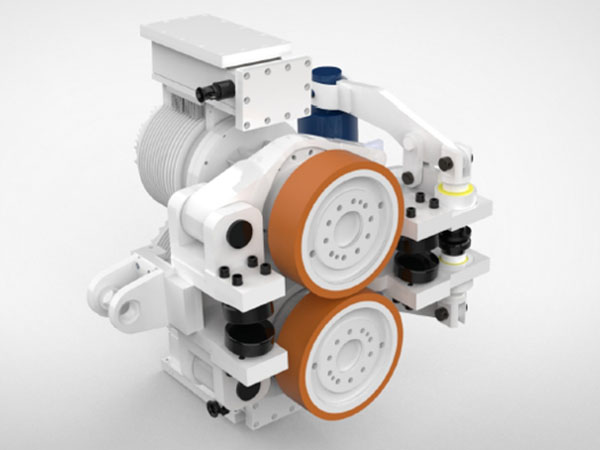

Standard Duty Wheels: These wheels are suitable for general use and provide a balance of load capacity and maneuverability.

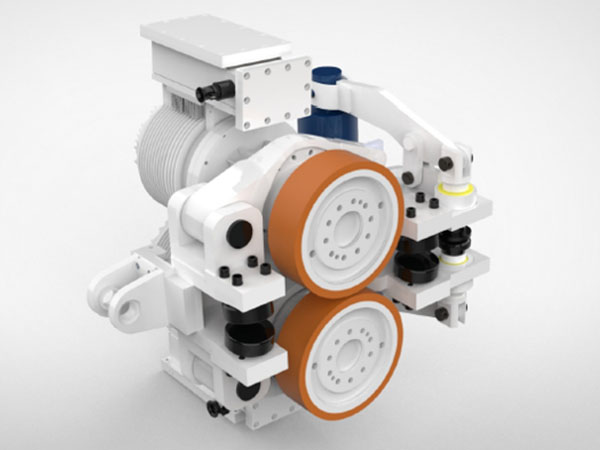

Heavy-Duty Wheels: Built to handle the most demanding loads, these wheels are ideal for large-scale mining operations.

Shock Absorbing Wheels: Designed with additional cushioning, these wheels are perfect for uneven terrain and heavy loads, ensuring a smooth ride.

Precision Wheels: For applications requiring high accuracy in the positioning of loads, precision wheels minimize rolling resistance and ensure consistent performance.

Flanged Wheels: Featuring a flange to prevent derailment, these wheels offer increased safety and stability on the monorail.

Custom Wheels: For specialized mining applications with unique requirements, custom polyurethane wheels can be manufactured to meet specific dimensions and performance criteria.

Remember, it's always important to consider the specific needs of your application when choosing the right wheels. We Philson in-house team is here to assist you in selecting the ideal monorail cranes polyurethane wheels that meet your requirements. For even more specialized polyurethane wheels, free to contact us to get relevant information.