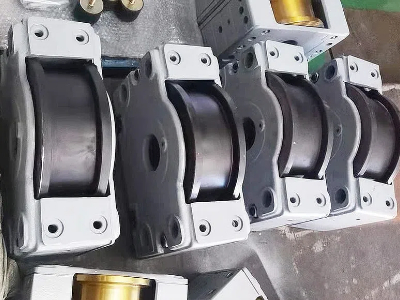

DRS 125-A30-A-60-K-X-A10 Crane Wheel Set

The DRS 125-A30-A-60-K-X-A10 wheel set is designed for industrial crane systems and is widely used in bridge cranes, gantry cranes, and suspension cranes. Its modular structure and high load capacity make it an ideal choice for medium and light lifting equipment, especially for occasions that require flexible adaptation to the track system and strict requirements on operating stability.

Simple installation and alignment, favorable dimensions, and a variety of universal connection options make our wheel system particularly cost-effective. The wide range covers wheel loads up to 60 tons.

DRS 125-A30-A-60-K-X-A10 product parameters

Manufacturer: Philson

Type: Wheel block system

Model: DRS-M-125-A30-A-60-K-X-A10

Wheel diameter: 125 mm

Dimensions (a1×b1) 220 mm×60 mm

Ground clearance (h1) 147.5 mm

Weight: 9.9 kg

Maximum load: 5 tons

Guide wheel: None

Casing: Ductile iron

Type: Flange on both sides, ductile iron

Variation: Top connection wheel block

PS: Equipped with deep groove ball bearings with lifetime lubrication to reduce maintenance frequency.

Advantages of the DRS 125 wheel

High load capacity and durability

The DRS 125 wheel box has a load capacity of up to 5 tons. The wheel diameter is 125 mm and is made of ductile iron (GGG 70). It has high strength and wear resistance and can withstand heavy load impact for a long time without deformation. The wheel tread can be specially hardened to meet the needs of high-speed operation.

Torsion and impact resistance

The optimized box design and torsion bracket structure effectively disperse the horizontal force and avoid track damage. For example, the DRS-M 200 can withstand 20% of the horizontal force of the wheel load, and the design of the DRS 125 also inherits this impact resistance.

Modular design

As a member of the DRS-M series, the DRS 125 supports full compatibility with other models (such as DRS-M 112, 160, 200), and can be flexibly adapted to different crane structures through a variety of connection methods (top connection, pin connection, end connection, etc.), significantly shortening the installation time.

Precise installation and convenient maintenance

• Laser calibration system: ensures precise alignment of the wheel box and the track with a tolerance of 1mm.

• Alignment fixture: no need to readjust the position when replacing the wheel box, greatly reducing downtime.

• Mechanical wear indicator: intuitively displays the wear status of the wheel through color codes, which is convenient for maintenance personnel to quickly diagnose.

If you want to know more about the model parameters of the "wheel block system", please contact our manual customer service.