Polyurethane AGV Drive Wheels for Material Handling

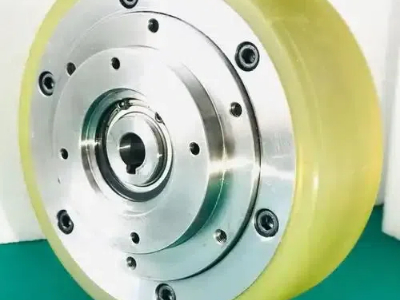

Polyurethane AGV drive wheels for material handling are revolutionizing automated guided vehicle (AGV) systems, delivering precision, durability, and energy efficiency in demanding industrial environments. Polyurethane AGV drive wheels for material handling are crafted from cast polyurethane 80-95 Shore A, a material range optimized for high load capacity, shock absorption, and minimal wear. Polyurethane wheels for material handling integrate a steel core with ball bearings, ensuring smooth rotation, reduced friction, and extended operational life even under heavy loads.

Superior durability and traction of PU injection wheels

Polyurethane AGV drive wheels for material handling excel in environments requiring consistent traction and floor protection. The injected polyurethane wheels manufacturing process guarantees dimensional accuracy and uniform density, critical for seamless integration with AGV systems. Polyurethane AGV drive wheels for material handling resist abrasion, deformation, and chemical exposure, outperforming traditional rubber or plastic wheels in high-traffic warehouses, manufacturing plants, and cold storage facilities.

Energy efficiency and adaptability of poly wheels

The polyurethane drive wheel design minimizes rolling resistance, reducing AGV battery consumption and supporting sustainable operations. Polyurethane AGV drive wheels for material handling maintain grip on polished concrete, oily surfaces, or uneven terrain, preventing slippage during rapid stops or directional changes. Their vibration-damping properties also protect sensitive cargo from damage during transport.

Customization for heavy-duty applications

Polyurethane AGV drive wheels for material handling are customizable to handle loads exceeding 1,000 kg per wheel, thanks to the cast polyurethane 80-95 Shore A formulation. The steel core with ball bearings enhances load distribution, reduces heat buildup, and prevents premature bearing failure. Polyurethane AGV drive wheels for material handling are ideal for automotive assembly lines, e-commerce fulfillment centers, and aerospace logistics, where reliability is non-negotiable.

Compatibility with modern AGV systems

Polyurethane AGV drive wheels for material handling are compatible with omnidirectional and differential drive systems, enabling agile navigation in tight spaces. The injected polyurethane wheels ensure balanced performance at high speeds. Their lightweight yet robust construction reduces long-term maintenance costs, as they last up to three times longer than conventional alternatives.

Trusted manufacturer: Philson

For polyurethane AGV drive wheels for material handling, Philson stands as a global leader. Philson’s expertise in cast polyurethane 80-95 Shore A formulations and steel core with ball bearings engineering ensures wheels that exceed industry standards. Philson’s injected polyurethane wheels are trusted by fortune 500 companies for their reliability, customization options, and cost-effectiveness. Whether optimizing AGV fleets or upgrading material handling systems, Philson delivers solutions that drive efficiency and longevity.