Stacker wheel blocks are mainly: 160-500mm, which can be used in special environments such as high temperature and extreme cold in the temperature range of -30°C to +200°C , and can also be used in explosion-proof crane drive devices. The travel wheel block can meet the requirements of stacker's high-speed and stable running. The stacker drive wheel block can bear a weight of 3000 kg-5t per wheel.

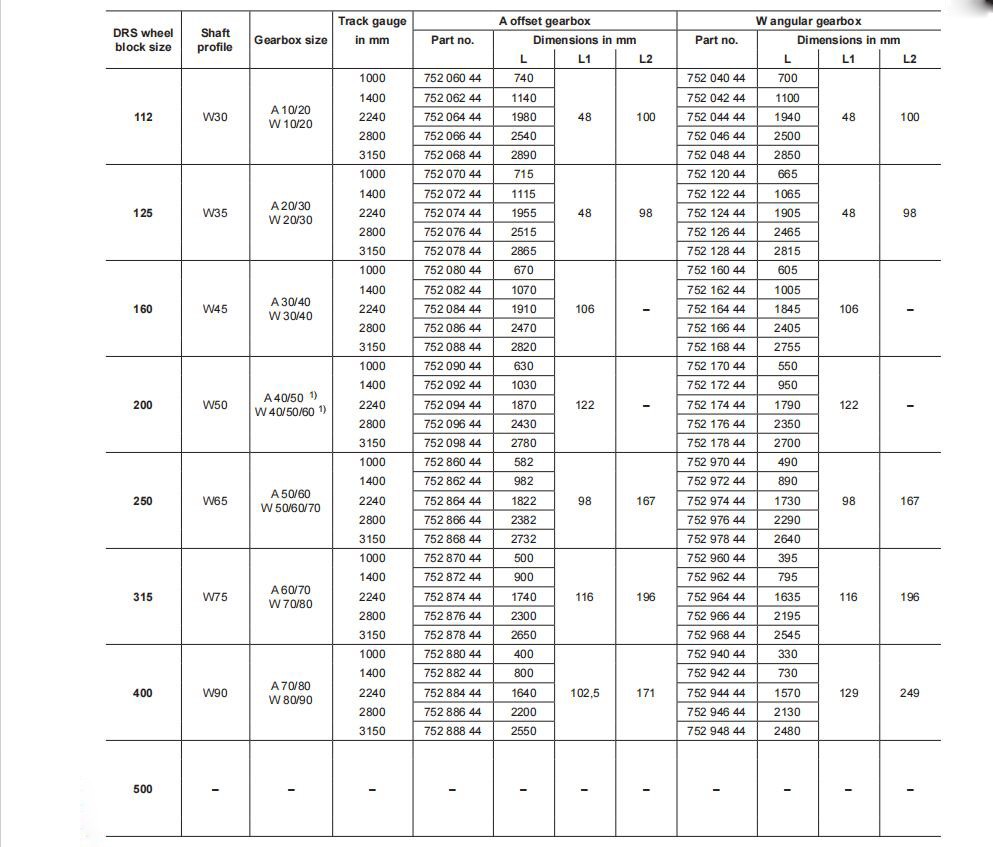

Stacker Travelling Wheel Block Model

The main models of the travelling wheel block are: 112mm,125mm,160mm, 200mm, 250mm, 315mm, 400mm and 500mm.

Stacker Wheel Block Material

The stacker wheel block is made of forged steel or cast iron, fitted with precision tapered bearings. Selecting a specific model based on load bearing capacity and wheel diameter. stacker wheel block is equipped with good wear resistance, non-bonding, non-degumming, tear resistance, corrosion resistance and other excellent properties to meet the needs of 24 hours of high-intensity work.

Stacker Wheel Blocks Assembly

- Torque brackets for connection to parallel and ac shaft reduction motors

-Horizontal guide wheel

- Buffers of various sizes and designs

- Track cleaning system

- Solutions for high temperature applications

- Walking wheels with reinforced design

To find out more about how our stacker wheel block can be customised for you, get in contact with our team today on 86 18994813198.