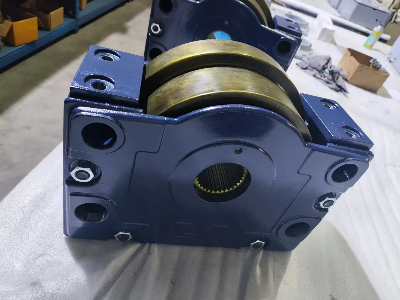

Professional Forged DRS Crane Wheels

Professional forged DRS crane wheels are engineered to provide outstanding durability, reliability, and performance in the most demanding industrial environments. Made from premium forged steel, these wheels are designed to withstand the extreme stresses and heavy loads encountered by industrial cranes, ensuring smooth operation and long service life. The precision engineering of DRS Crane Wheels ensures that cranes can maintain operating efficiency while minimizing wear, which is critical to reducing maintenance costs and increasing productivity.

What makes professional forged DRS crane wheels stand out?

One of the main features of professionally forged DRS crane wheels is their rugged design. The forging process involves heating the steel billet to an optimal temperature and then precision forming it using a hydraulic press. After forging, the wheels are quenched, tempered, and machined to exact specifications. Forged wheels are not only stronger than cast wheels but are also more resistant to deformation under heavy loads. This makes them ideal for overhead cranes, gantry cranes, and other material handling systems that operate in harsh, high-load environments.

Forged DRS crane wheels are designed to integrate seamlessly with a variety of crane systems, ensuring smooth operation without compromising the integrity of the wheel itself. The high-strength steel used in their construction enables them to handle heavy loads with ease, reducing the risk of failure and increasing safety on the job site

Key benefits of using forged DRS crane wheels

• Enhanced load capacity: Forged wheels have superior load-bearing capacity, which is critical for cranes used in heavy lifting operations. Whether in construction, shipping, or heavy manufacturing, these wheels can handle large weights without compromising structural integrity. The DRS Series wheels can carry loads ranging from 2.75t to 40t.

• Precision engineering: Tolerances of 1mm or less and smooth surfaces minimize friction, extending the life of the track and wheel.

• Improved performance: DRS crane wheels are designed for smooth, efficient rotation. This reduces friction, which improves overall performance and increases operating efficiency.

• Custom options: Whether you need wheels for standard overhead cranes or specialized gantry cranes, sizes, heat treatments, and hardness grades can be customized to fit specific crane configurations.

• Invest in long-term reliability: By prioritizing forged DRS crane wheels, industries can reduce maintenance costs and unplanned downtime. Partner with a trusted manufacturer to ensure certified, traceable components backed by technical expertise.

For industries that require high-performance, durable, and efficient crane wheels, specialized forged DRS crane wheel blocks are the ideal solution. With rugged construction, long service life, and the ability to withstand high loads, these wheels are essential components to ensure cranes operate smoothly and safely in challenging environments.