What Are Urethane Skid Conveyor Rollers?

Urethane skid conveyor rollers are specialized rollers coated with polyurethane material, designed to reduce friction and wear on conveyor belts and skids. Unlike traditional steel or rubber rollers, urethane rollers offer superior abrasion resistance and durability, making them ideal for high-wear applications.

Key Features of Urethane Skid Conveyor Rollers

Abrasion Resistance: Urethane provides a hard-wearing surface that resists damage from constant friction and heavy loads.

Low Friction Coefficient: The smooth surface of urethane reduces the friction between the roller and the conveyor belt or skid, resulting in smoother operation and reduced energy consumption.

Chemical Resistance: Urethane coatings are resistant to oils, greases, and other chemicals, ensuring the rollers maintain their integrity in harsh environments.

Shock Absorption: The elastic properties of urethane help absorb shocks and vibrations, protecting the roller core and extending the lifespan of the conveyor system.

Customizability: Urethane rollers can be tailored to specific hardnesses and diameters, depending on the application requirements.

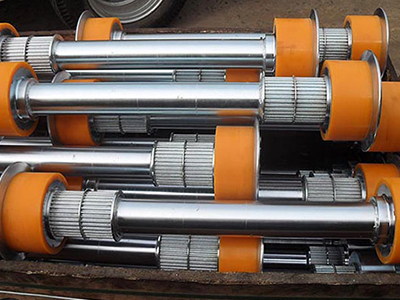

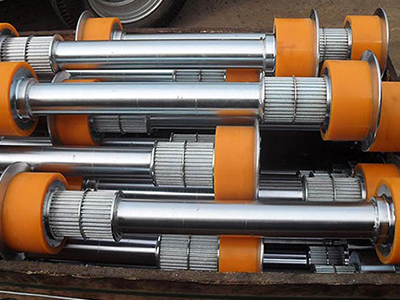

Urethane skid conveyor rollers

Philson urethane skid conveyor rollers & polyurethane coated rollers are excellent for the handling of skids and pallets. In addition to competing with industry leaders in terms of weight capacity, our rollers are also capable of standing up to the most trying cycle requirements, including rapid starts and stops.

Our urethane skid conveyor rollers can be matched to almost any dual line conveyor system. They are available for coating in a variety of high grade polyurethanes and are normally driven by a series of toothed belts.